High Density Aircraft Tool Tungsten Heavy Alloy Bucking Bars, Customized

Product Description

Tungsten bucking bars provide increased weight (density) to allow riveting in confined areas. The weight to size ratio provides a good kinetic energy transfer to expedite the rivet installation process. Our Tungsten bucking bars greatly reduce the vibration caused by driving rivets reducing or eliminating damage to the hand. They are precision ground with polished surface fora professional look in your set rivets. Kefeng tungsten bucking bars are available in standard sizes and shapes customized or clients drawings.

High-density ergonomic tungsten bucking bar rivet blocks reduce vibration and kickback while riveting in aircraft operations. Repeated vibrations can cause wrist strain and fatigue, and regular steel bucking bars don't fully protect the riveter from the harmful effects. Tungsten material bucking bars, over twice as dense as normal steel, absorbs the shock, allowing you to rivet more effectively for a longer period of time.

Characteristics and features

Tungsten alloy offer the maximum density available, these tungsten alloy bars are more than twice as heavy as an identical bar made of steel, small size and high density make the bars can fit small areas.

Small size and same weight ,tungsten alloy bucking bars reduce the recoil when reflecting the impact back to the rivet shaft. Bars that are more massive can reduce vibration transmitted to the hand. Tungsten alloy bucking bar makes any riveting process much easier, provide a good kinetic energy transfer to expedite the rivet installation process thus can greatly reduce the vibration caused by driving rivets and eliminate damage to operators’ hands.

1. High temperature resistance

2. High impact and crack resistance

3. Shock and corrosion resistance

4. Good modulus of elasticity and high hardness

Application

The Hand Tool Riveting Tool Tungsten Bucking Bars are mostly used in aviation, aerospace and aircraft industries. Other applications for tungsten heavy alloy machining parts:

1. Radiation shielding

2. Containers of radioactive isotopes

3. High performance projectiles for underwater hunting

4. Gyro components

5. Balance weights for racing boats and racing cars

6. The optical industry like microscopes and measuring instruments

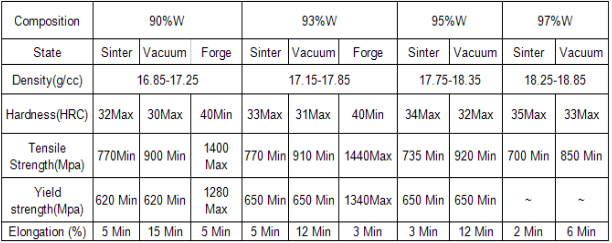

Technical parameters

Tungsten heavy alloy |

WNiFe (ASTM B777, AMS-T-21014) |

WNiCu (ASTM B777, AMS-T-21014) |

|||||

Designation |

90W |

93W |

95W |

97W |

90W |

93W |

95W |

Density g/cm3) |

16.85~17.30 |

17.15~17.85 |

17.75~18.35 |

18.25~18.85 |

16.85~17.30 |

17.15~17.85 |

17.75~18.35 |

Tensile Strength (MPa) |

758Min |

758Min |

724Min |

689Min |

648Min |

648Min |

684Min |

Elongation (%) |

5Min |

5Min |

3Min |

2Min |

2Min |

2Min |

1Min |

Hardness (HRC) |

32Max |

33Max |

34Max |

35Max |

32Max |

33Max |

34Max |

Yield strength(MPa) |

517Min |

517Min |

517Min |

517Min |

517Min |

517Min |

517Min |

description2